보유기술

에너지 효율개선사업

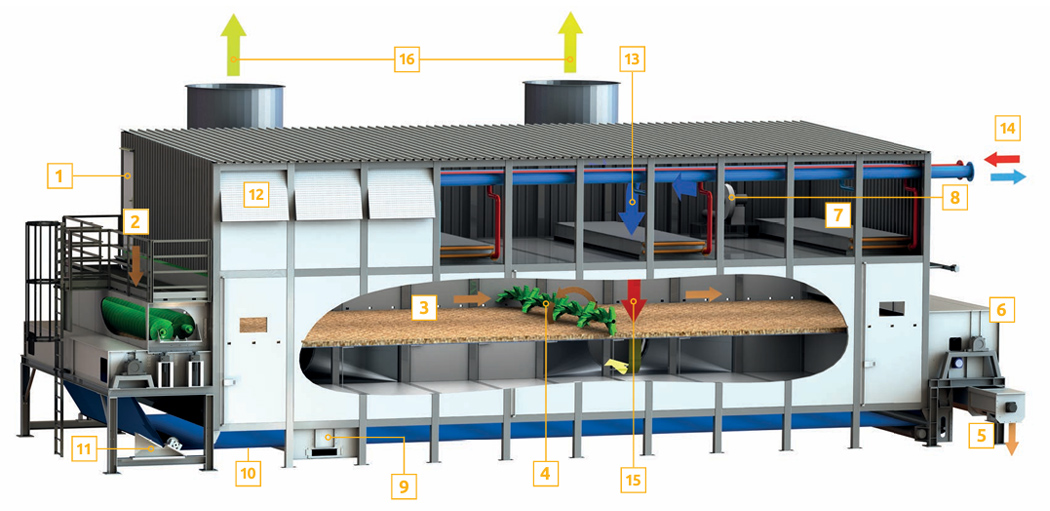

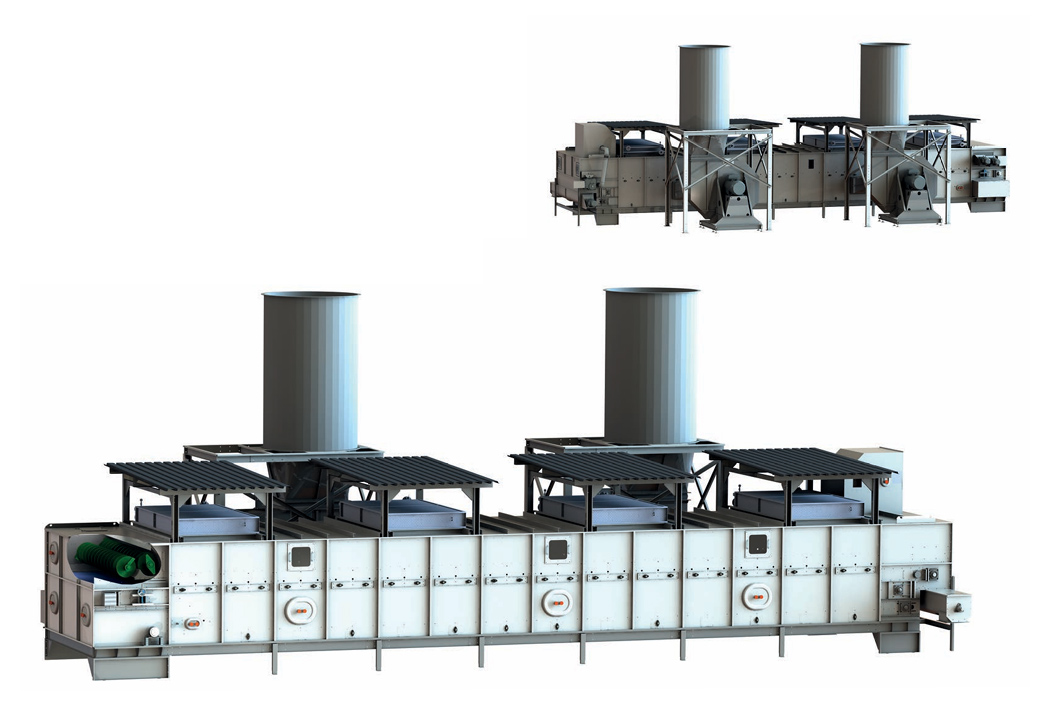

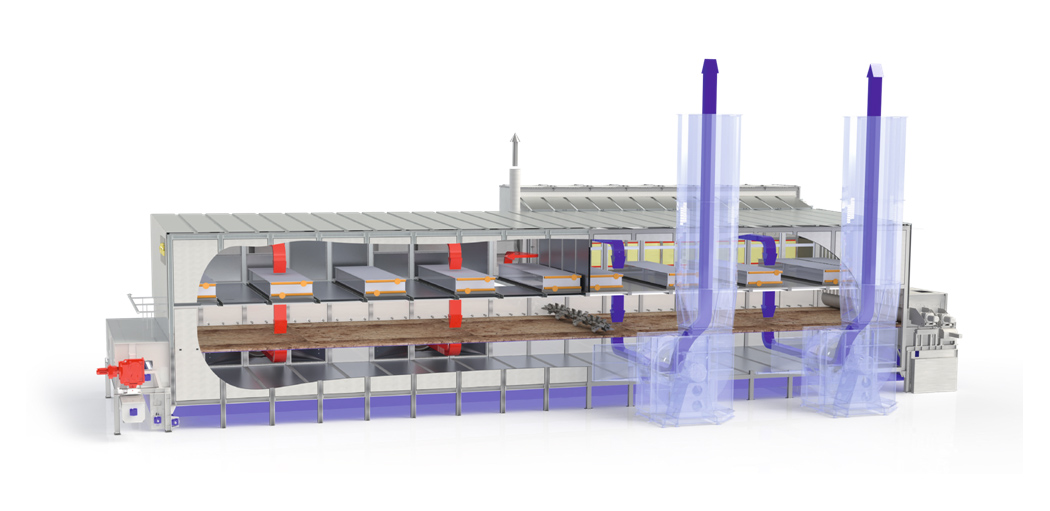

Belt dryer type BT

Characteristic features

Efficient air distribution due to direct-coupled and frequency-controlled multi-vent radial fans

Modular concept that can be easily extended

Low heat and electricity consumption thanks to perfectly matched components

Large doors for easy maintenance

Enclosed design allows for exterior installation at temperatures as low as -40 °C (insulated dryer tunnel)

Optimal product distribution due to double distribution screws

Product-turning device for consistent fi nal moisture content and energy-effi cient product ventilation

Top-down ventilation

- 1 : Maintenance access

- 2 : Feeding station

- 3 : Product

- 4 : Turning device

- 5 : Discharge screw

- 6 : Belt cleaning system (dry)

- 7 : Heat exchanger

- 8 : Fan for belt cleaning system

- 9 : Belt cleaning system (wet)

- 10 : Web belt

- 11 : Belt alignment

- 12 : Fresh air intake

- 13 : Fresh air

- 14 : Heat supply

- 15 : Drying air

- 16 : Exhaust air

- 17 : Exhaust air fan

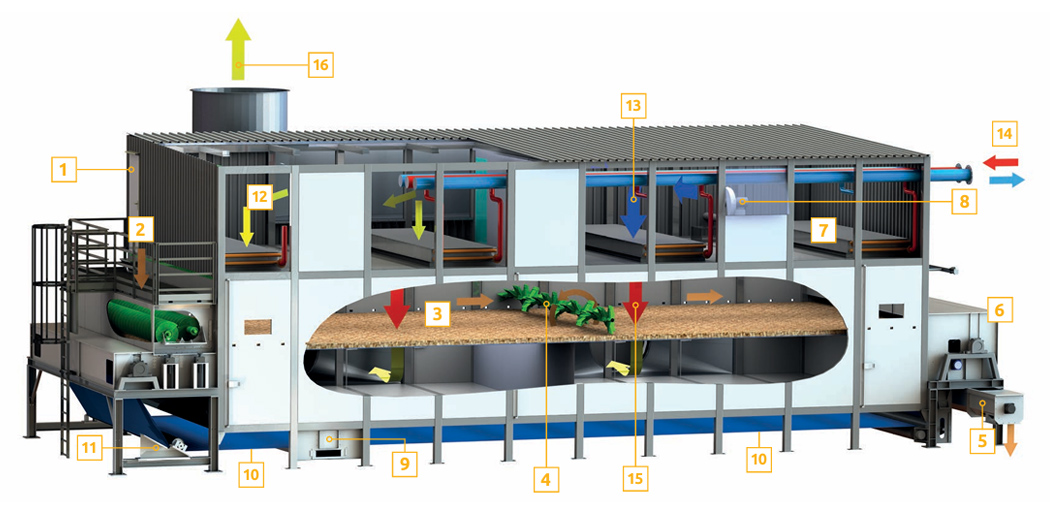

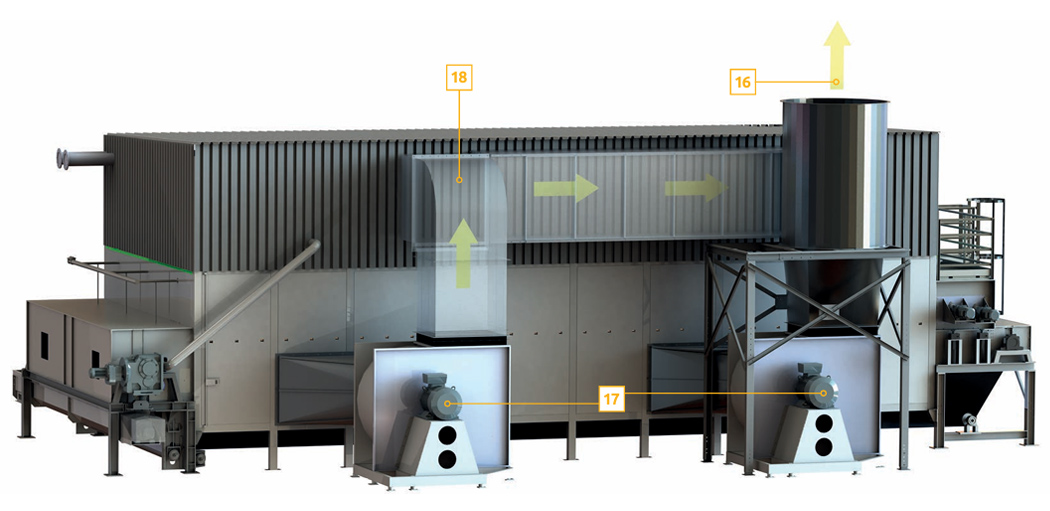

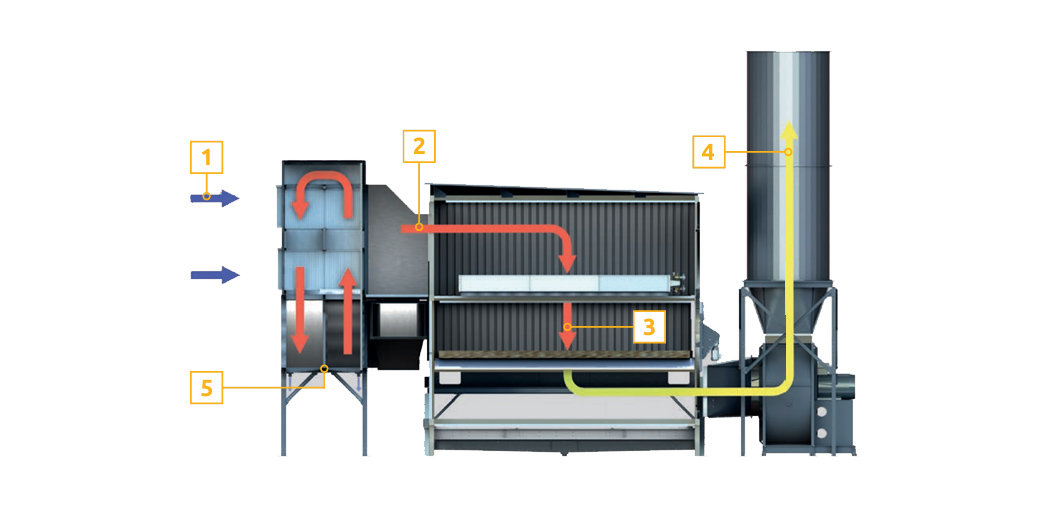

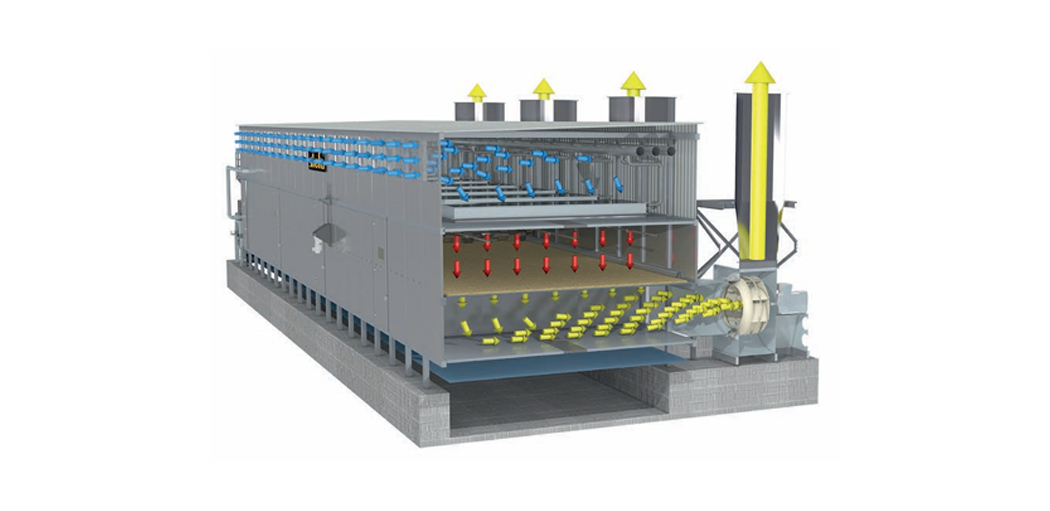

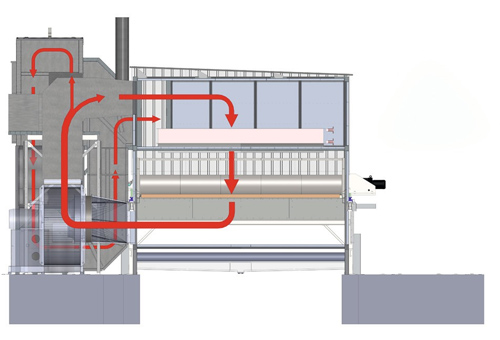

Belt dryer type BTU with air recirculation for heat recovery

Characteristic features

Reduced exhaust air volume

Reduced emission mass fl ows

Reduced specifi c thermal energy consumption

Large doors for easy maintenance

Enclosed design allows for exterior installation at temperatures as low as -40 °C (insulated dryer tunnel)

Optimal product distribution due to double distribution screw

Product-turning device for consistent fi nal moisture content and energy-effi cient product ventilation

Top-down ventilation

- 1 : Maintenance access

- 2 : Feeding station

- 3 : Product

- 4 : Turning device

- 5 : Discharge screw

- 6 : Belt cleaning system (dry)

- 7 : Heat exchanger

- 8 : Fan for belt cleaning system

- 9 : Belt cleaning system (wet)

- 10 : Web belt

- 11 : Belt alignment

- 12 : Fresh air intake

- 13 : Fresh air

- 14 : Heat supply

- 15 : Drying air

- 16 : Exhaust air

- 17 : Exhaust air fan

- 17 : Circulating air

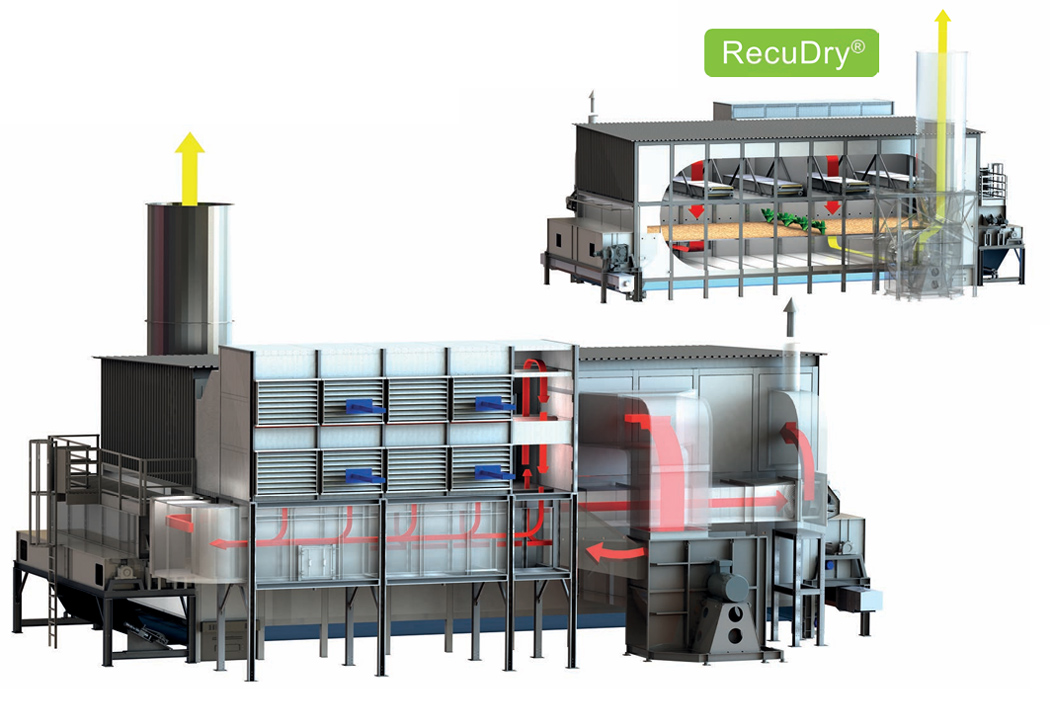

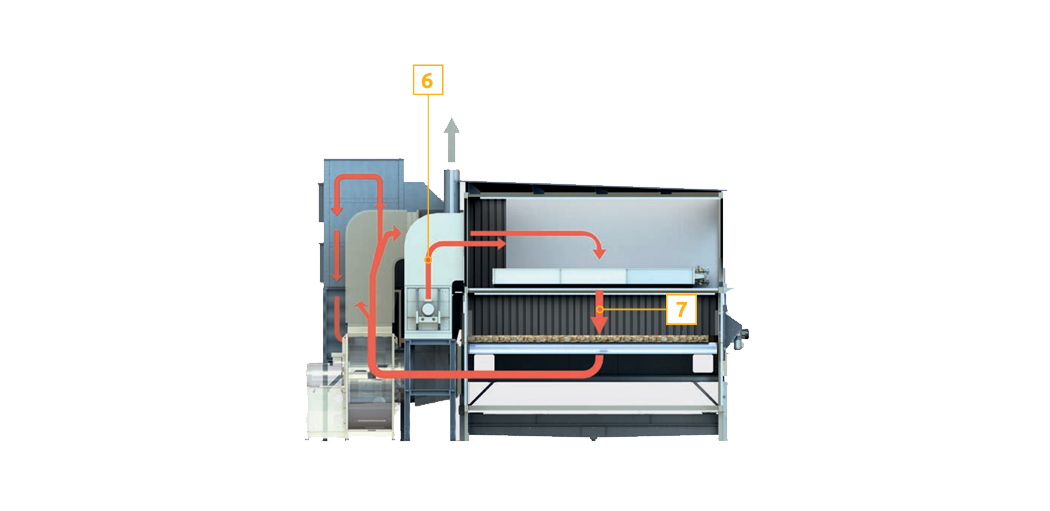

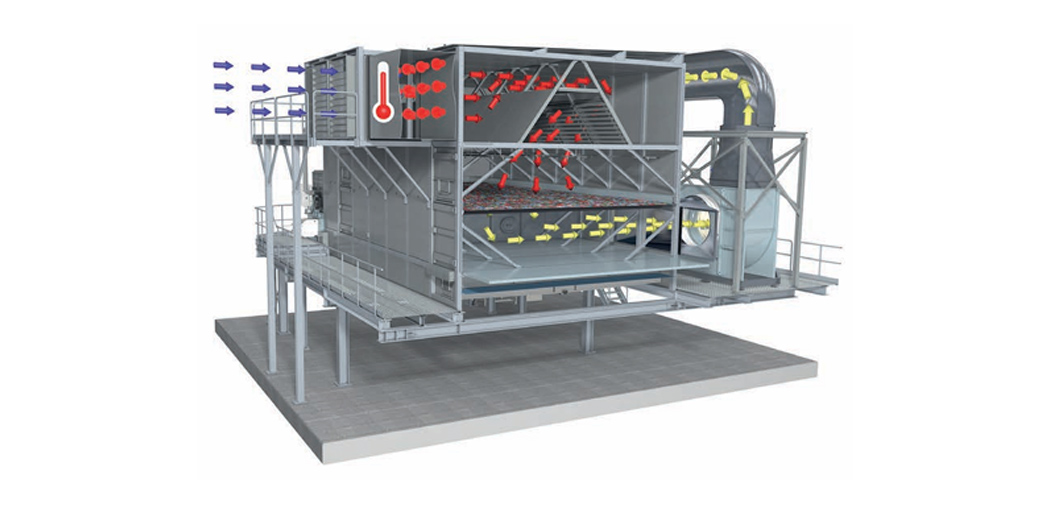

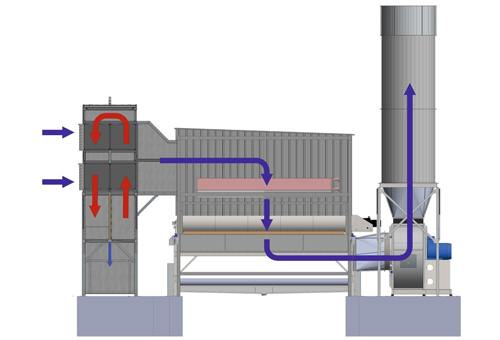

Belt dryer type BTU RecuDry® with air recirculation for heat recovery and condensation

Characteristic features

Conventional drying technology separated into two drying areas:

1. CONDENSATION MODULE:

Latent energy is used to pre-heat the fresh air

Maximum drying effi ciency due to the majority of the energy utilized being recovered with an air-to-air heat exchanger

Energy savings of 35–55 %, depending on the net drying area

Low exhaust air volumes and emissions

Retrofi tting option for existing systems with the RecuDry® system

- 1 : Fresh air

- 2 : Pre-heated fresh air

- 3 : Drying air

- 4 : Exhaust air

- 5 : Recu air

- 6 : Condensed Recu air

- 7 : Drying air Recu

2. RECU MODULE:

Optimal saturation using circulation and reheating

Use of this energy-rich air in the condensation module

RecuDry® Advanced design without reheating

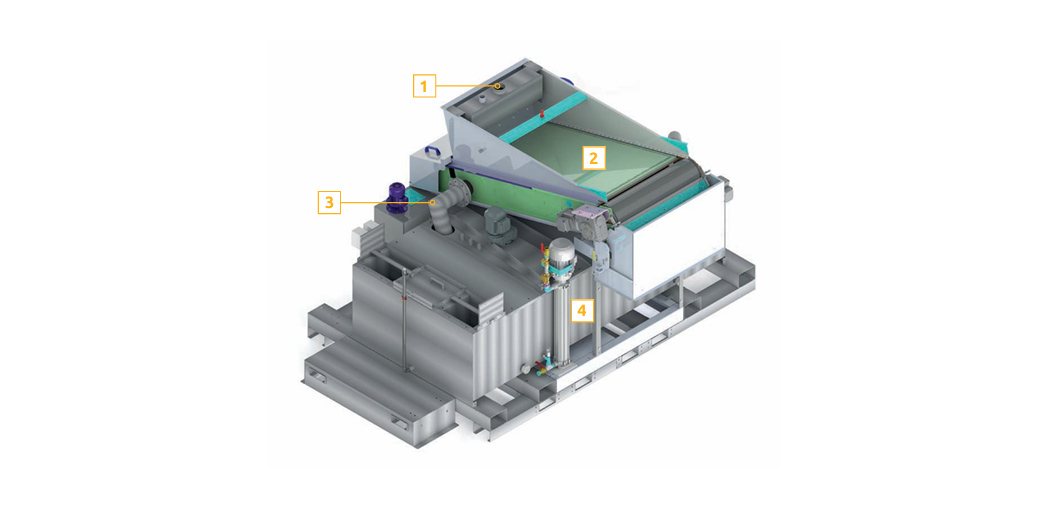

Belt dryer type BTU RecuDry®with air recirculation for heat recovery and condensation

Functionality of the condensate treatment

Belt filter with neutralisation unit

Serves to clean and treat continuously produced condensate from the condensation modules as well as contaminated wash water from the cleaning unit

Addition of caustic soda for neutralisation

Excess is discharged via waste water pipe

Treated condensate is used to clean the heat recovery system

- 1 : Condensate inlet

- 2 : Belt filter

- 3 : Condensate outlet

- 4 : Condensate collecting basin

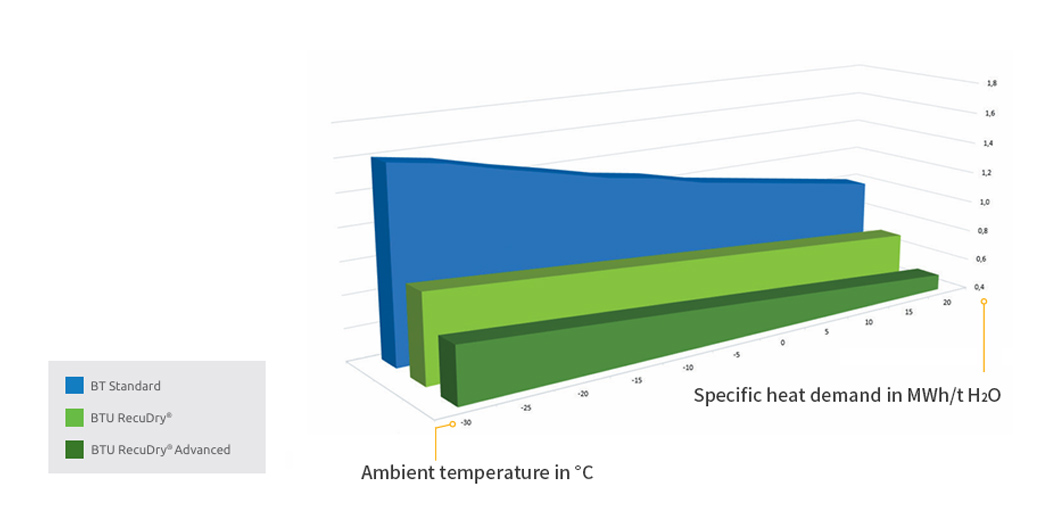

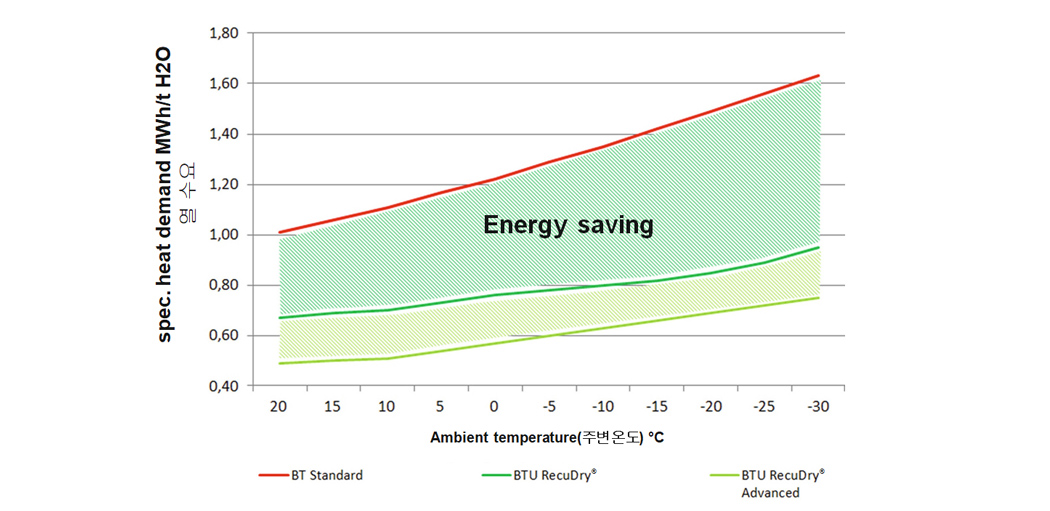

Energy saving compared to other belt dryers

Exemplary illustration of energy saving

Comparison of a drying system’s energy demand in a wood-pelleting plant based on a heat supply with 90 °C hot water:

Compared to the stela BT standard, stela BTU RecuDry® yields energy savings of 35 % during summer and 40 % during winter months, depending on the outside temperature.

Energy savings of up to 55 % can be achieved with the stela RecuDry® Advanced System by further increasing the drying area.

- stela Standard drying system compared with stela BTU RecuDry®and stela BTU RecuDry® Advanced.

Belt dryer type BTL

Characteristic features

Cost-eff ective drying system in the lower and medium output ranges

Modular concept that can be easily extended

Top-down ventilation

Optimal product distribution due to double distribution screws

Product-turning device for consistent fi nal moisture content and energy-effi cient product ventilation

Indirect drying

Use fi nned pipe heat exchangers

For hot water up to 130℃

For hot water from cogeneration or fl ue gas condensation

For saturated steam up to 15 bar

Plate heat exchangers can be used for special media (geothermal energy, thermal oil)

Direct drying

With hot air > 120℃

The raw gas temperature is homogenised with fresh air in a mixing chamber

For example, brick cooling air is used prior to dust extraction in cement plant

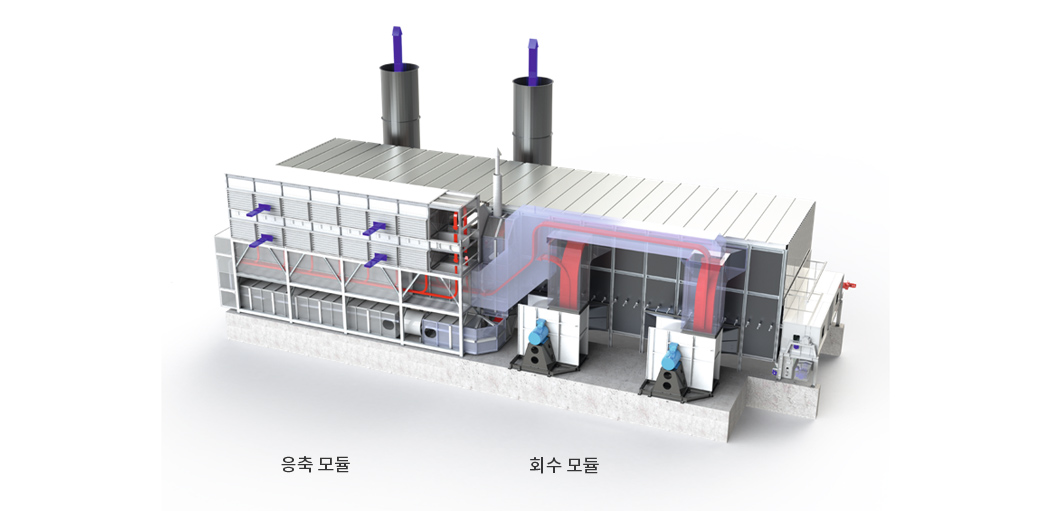

Low Temperature Belt Dryer BTU RecuDry®

Advantages

RecuDry® 시스템은 기존 건조 기술을 두 가지 건조 영역으로 나눕니다.

Recu 모듈과 응축 모듈.

Recu 모듈에서는 순환과 재가열을 통해 건조 공기가 최적으로 포화됩니다. 이 고에너지 순환 공기의 일부는 응축 모듈로 향합니다. 포함된(주로 잠재 에너지) 에너지는 응축 모듈을 위한 신선한 공기를 예열합니다. 공기 대 공기 열 교환기를 사용하면 적용된 에너지의 대부분을 회수할 수 있으므로 매우 효율적인 건조 공정.

시스템의 특별한 이점:

건조 표면에 따라 35 – 55%의 에너지 절약

배기 공기 흐름 및 배출 감소

기존 건조 플랜트를 RecuDry® 시스템으로 업그레이드 가능성

System

-

Recu module

Recu module -

Condensation module

Condensation module

Energy saving

위에는 펠릿 공장 내 벨트 건조 공장의 예시적인 에너지 수요가 나와 있습니다(90°C의 온수를 이용한 열 공급).

빨간색 선은 표준 건조 시설의 열 수요를 나타냅니다. RecuDry® 시스템(녹색 선)을 사용하면 주변 온도에 따라 여름에는 35%, 겨울에는 40%를 절약할 수 있습니다. 응축 모듈에서 예열된 공기의 재가열 감소와 건조 표면 증가로 인해 RecuDry® Advanced 시스템(밝은 녹색 선)을 사용하면 에너지 절감량이 최대 55%에 도달할 수 있습니다.

-

Energy saving 35 – 55 %

Energy saving 35 – 55 %